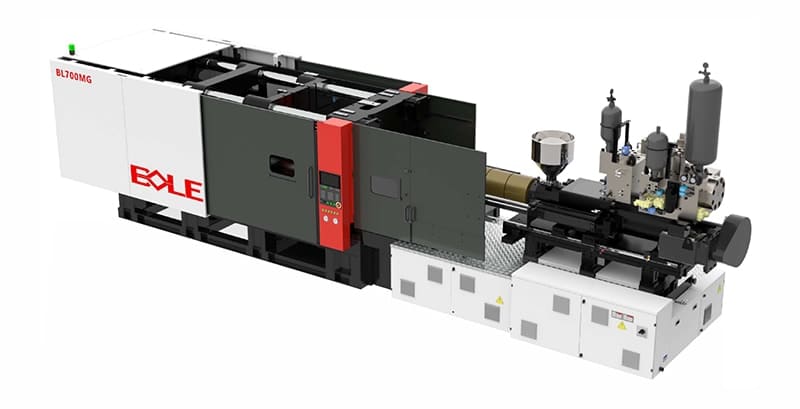

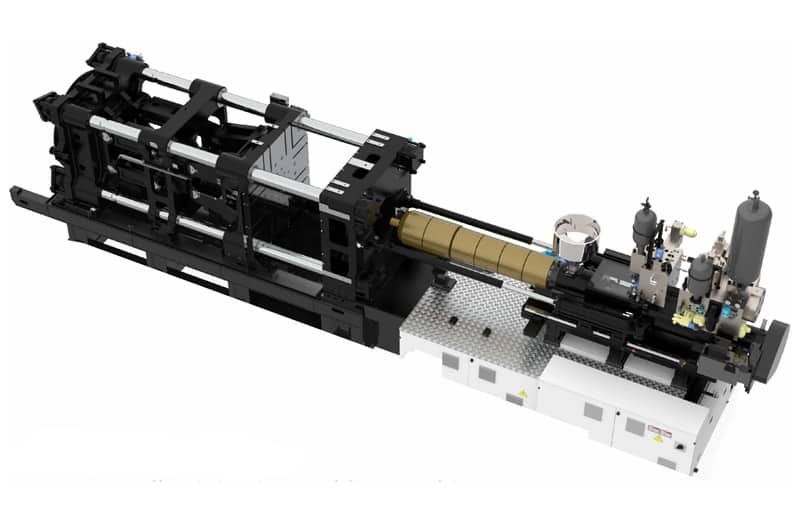

Did you know that BOLE is a leader in semi-solid magnesium injection moulding? With many years of experience, BOLE’s MG Series can make metal forming simple and convenient.

By utilising semi-solid injection moulding, BOLE customers can benefit from the increased tensile strength, stiffness, impact resistance and thermal conductivity of magnesium-aluminium alloy products.

Commonly used in applications such as defence, aerospace, automotive and electronics, the metal forming solution of the MG Series is safe, simple and precise. No melting furnace is required, enabling energy savings of 50% and space savings of 30% when compared to other technologies.

Key Features

Build configuration for UK

Standard FE All Electric machines

SERIES

MAIN PARTS

BRAND

MANUFACTURED COUNTRY

1

Computer

KEBA

AUSTRIA

2

Servo Motor

PHASE

ITALY

3

Servo Driver

PHASE

ITALY

4

Pressure Sensor

NMB

JAPAN

5

Ball Screw

LAIEN

CHINA

6

Contactor

SCHNEIDER

GERMANY

7

Breaker

SCHNEIDER

GERMANY

8

SSR

SCHNEIDER

GERMANY

9

Safety Relay

PILZ

GERMANY

10

Traveling Switch

PILZ

GERMANY

11

Promixity Switch (Square)

PILZ

GERMANY

12

Promixity Switch (Rounded)

PILZ

GERMANY

13

Plasticizing Motor

PHASE

ITALY

14

Mould-Adjusting Motor

PHASE

ITALY

15

Plasticizing Bearing

NSK

JAPAN

16

Sealing Ring

HALLITE/NOK

UK/JAPAN

17

Direction Valve

TOKYO KEIKI

JAPAN

18

Lubrication Pump

RUNZHOU

CHINA

19

High Pressure Pipe

MANULI/ALFA GOMMA

ITALY

20

Pressure Gauge

TECSIS

GERMANY

The world’s largest manufacturers trust Bole